Description

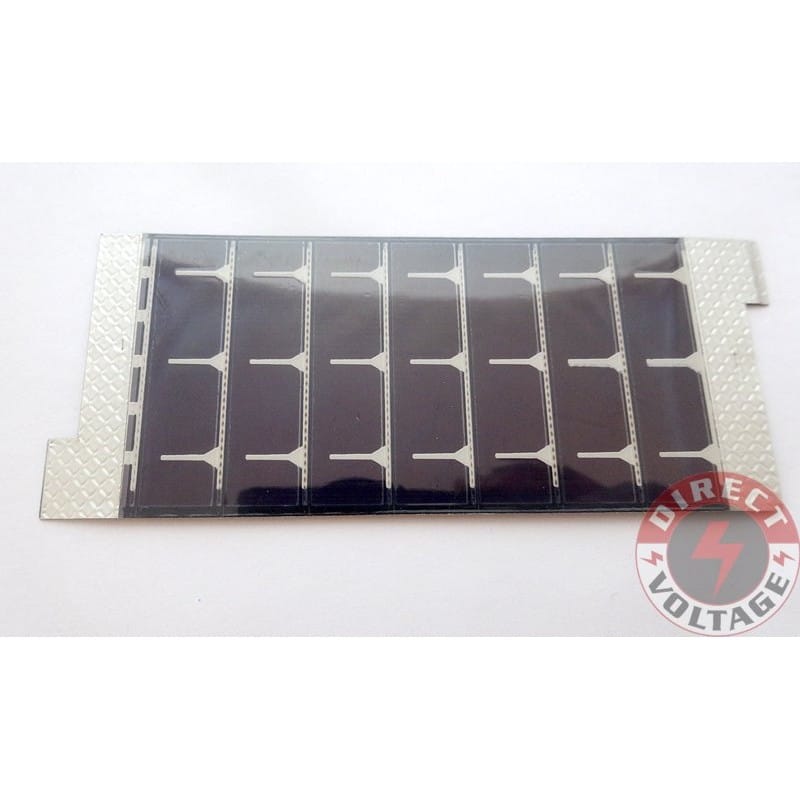

PowerFilm Solar OEM Module GN4.2-36 22mA @ 4.2V

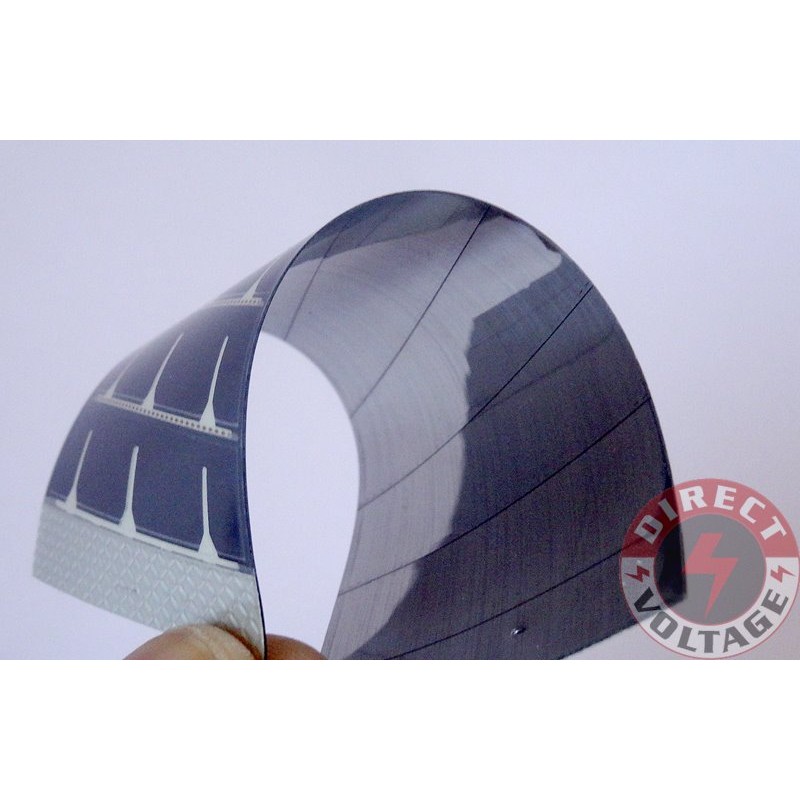

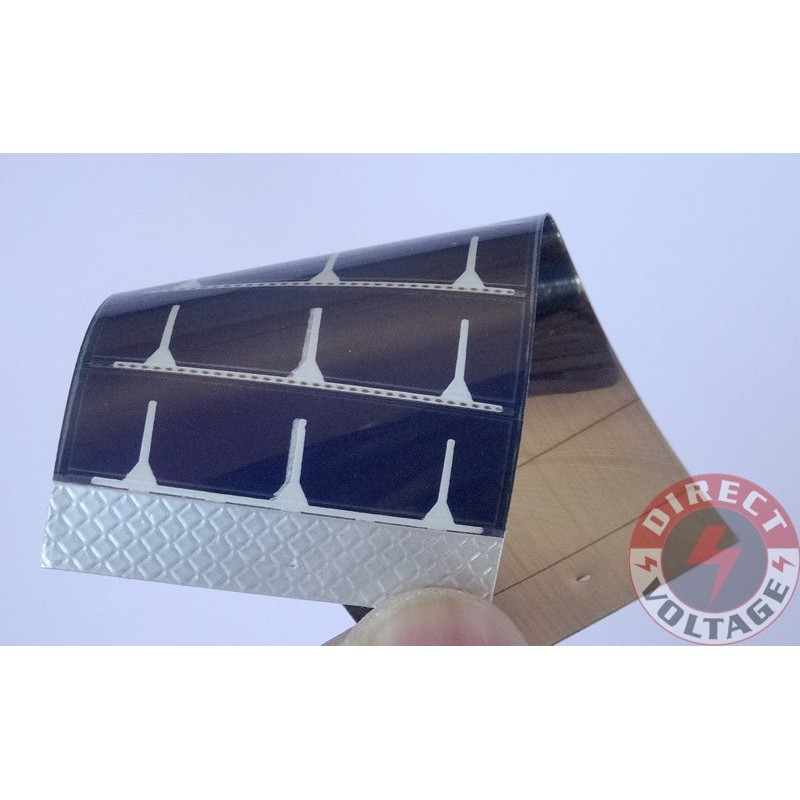

PowerFilm Wireless Electronic modules are lightweight, paper-thin, and durable. Their thin profile enables them to be easily integrated with devices for solar-recharging or direct power.

Solar modules used for OEM parts and products where an integrated power source is needed. Modules in the PowerFilm Wireless Electronics Series offer a new opportunity to solve the old problem of limited power for wireless electronics in both portable and remote electronic applications. These small flexible modules can be used in a variety of electronic applications. Each module offers 22mA @ 4.2V when exposed in full sunlight. Use for integration in OEM parts or products where a solar power source is needed. Perfect for models, prototypes, or inventions requiring power. Great for hobbyists!

Module :3.47in x 1.46in

Thin, lightweight, and flexible yet durable

Integrate into existing or prototype electronics

Each solar module is 22mA @ 4.2V when exposed in full sunlight.

GN4.2-36 Series Instruction

Leads and Testin

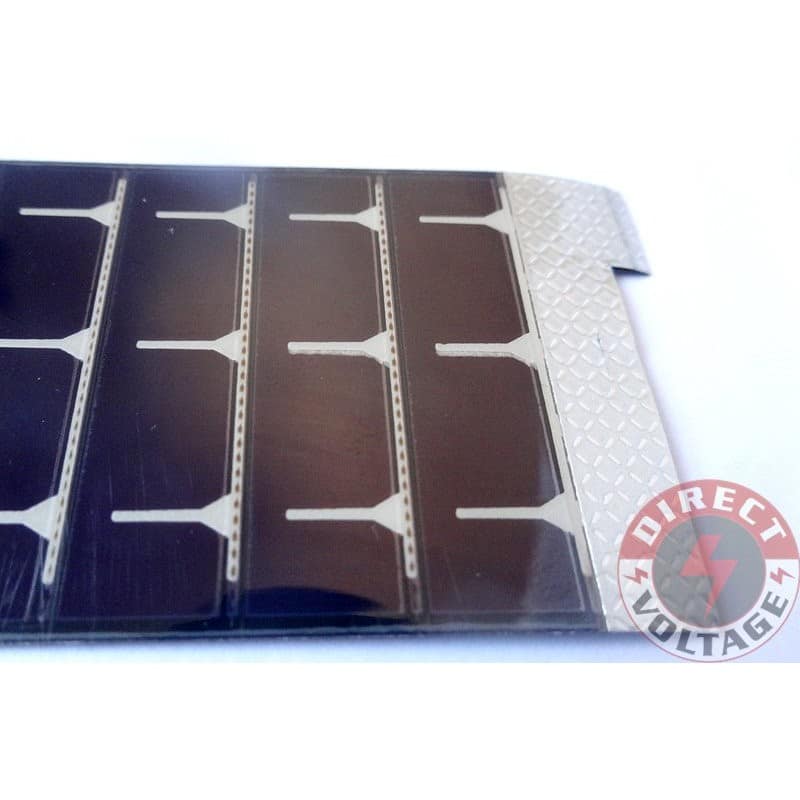

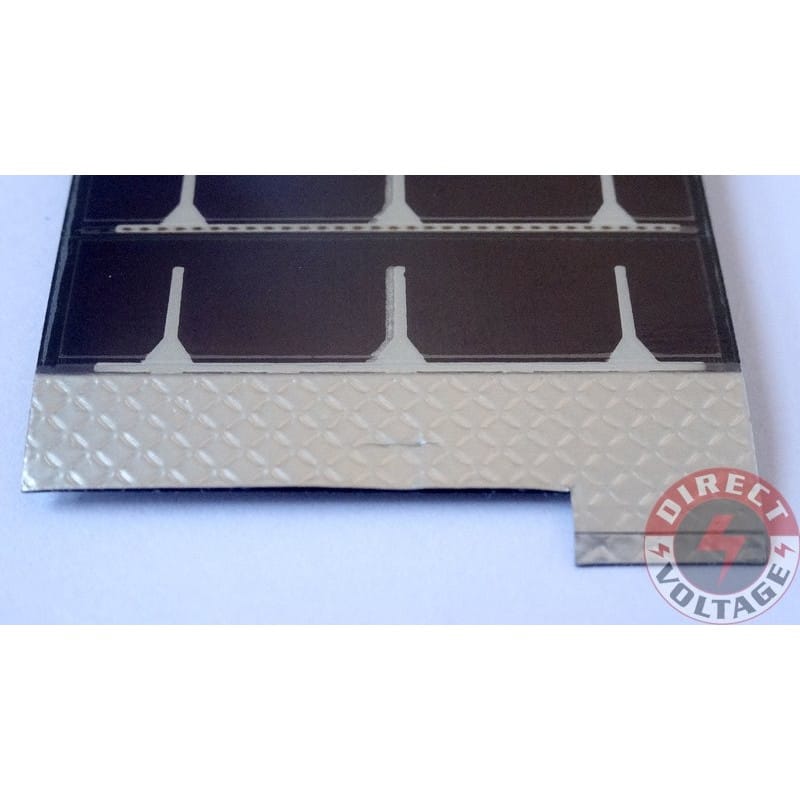

The leads on the modules in the PowerFilm® Wireless Electronics Series are the copper tape strips located at each end of the solar module. Remember to check the Polarity! To test the module using alligator clips for the connection to the tester, ensure the clips make direct contact with the copper tape. The coating over the copper tape will likely need to be scraped away to ensure direct contact.

Connecting the Module to a Load

Connection methods include soldering, crimping or using alligator clips. Remember to check the Polarity!

Module Polarity Information

It is extremely important to recognize the correct polarity of the PowerFilm® modules!The positive end of the solar module is shown in the diagram below. A diode, such as 1N5817, is recommended to prevent the solar module from draining the battery when the solar module is in the dark. A diode is not required for a battery-free electrical device. The positive end of the module connects to the positive end of the load. The negative end of the module is also shown in the diagram and should be connected to the negative end of the load. The recommended connector wire size is a minimum size of 24 gauge. As an extra measure, connect the solar module to a digital multimeter for polarity (+,-) identification. On solar modules with copper tape leads, remove a small piece of the clear coating that is on top of the copper tape to ensure good contact between the alligator clips of the digital multimeter and the copper tape

Soldering

The solar modules should be soldered to from the front. The positive copper contact is on one end and the negative is on the other end (see section on Polarity).

Use the hot tip of the soldering iron to melt through the clear coating over the copper tape. Be careful not to burn through more than just the thin clear coating. Burning too deeply can damage the solar module. Although not necessary, it is possible to remove a small piece of the clear coating with a sharp knife prior to soldering to the copper tape.

Good contact can be made by melting and depositing a dot of solder to the exposed copper tape.Use a low temperature soldering iron adjusted to about 600 to 650 degrees (F). It is also acceptable to solder directly to the copper tape, without using a solder dot.

Crimping

A pressure method of mechanically securing a terminal, splice or contact to the copper strips may be used.

Alligator Clips

Although not the most secure connection option, alligator clips may be used

Fastening the Module

The modules may be fastened in several ways: Epoxy, silicon, super glue, 3M super 77 spray, double-sided acetic tape, etc. Be sure to choose adhesive based on the material to which module is being attached. Also, be careful not to get any adhesive on the front side (dark side) of the module since it will degrade overall performance.

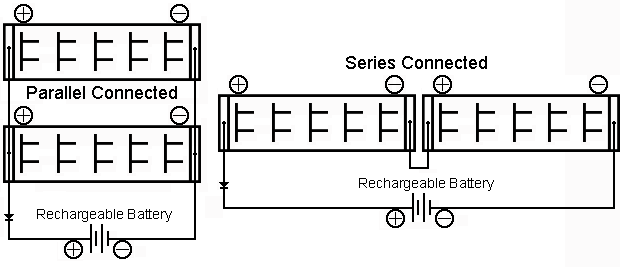

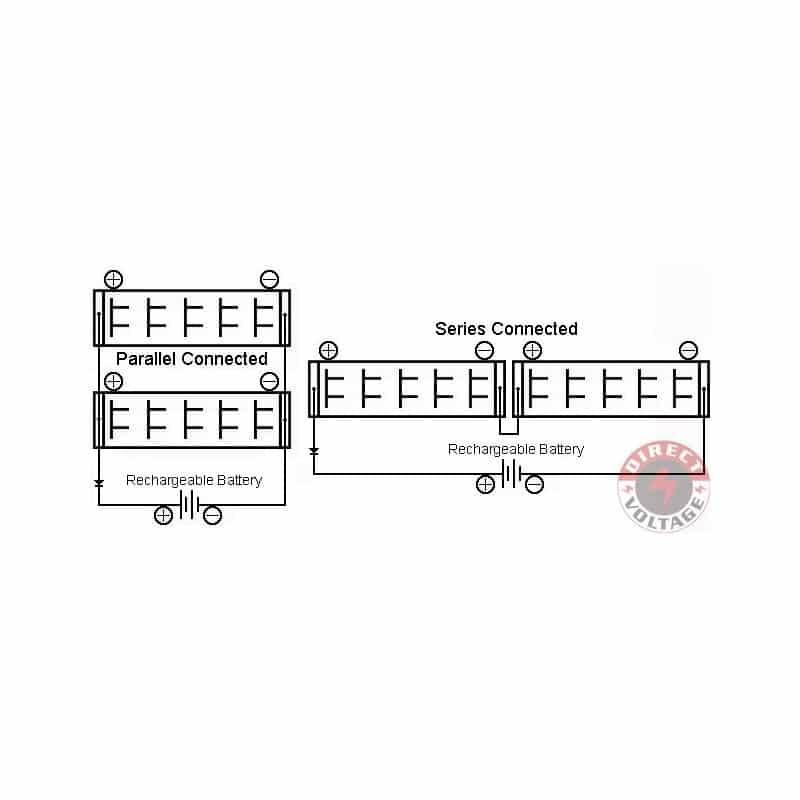

Connecting Modules for Higher Operating Voltage and Current

You can parallel and series connect solar modules to achieve higher voltage (series connected) or higher current (parallel connected). However, only put like modules together.

Parallel connecting two similar modules will double the output current and series connecting three identical modules will triple the output voltage.

Warning! We do not recommend series connecting solar modules for an output voltage greater that 48V. Voltages above this can be deadly

The diagram below graphically demonstrates parallel and series connected solar modules:

Reviews

There are no reviews yet.